freiform Werkzeugbau GmbH in Liqu. / Liquidator: Markus Ebnicher

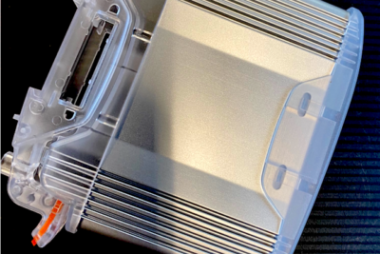

Kunstoff & Kautschuk

Wir liefern fertige Produkte aus den vielseitig verwendbaren Rohstoffen Kunstoff und Kautschuk.

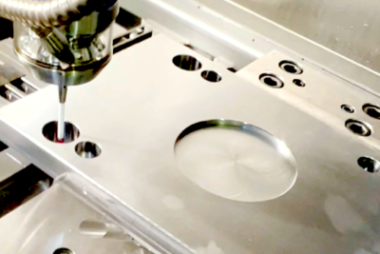

Graphit-Elektroden

Effiziente und kosteneffektive Lösungen mit Graphit-Elektroden für das Senkerodieren.

Oberflächenbearbeitung

Freiform bearbeitet auch Oberflächen mit dekorativen Eigenschaften für Sie.